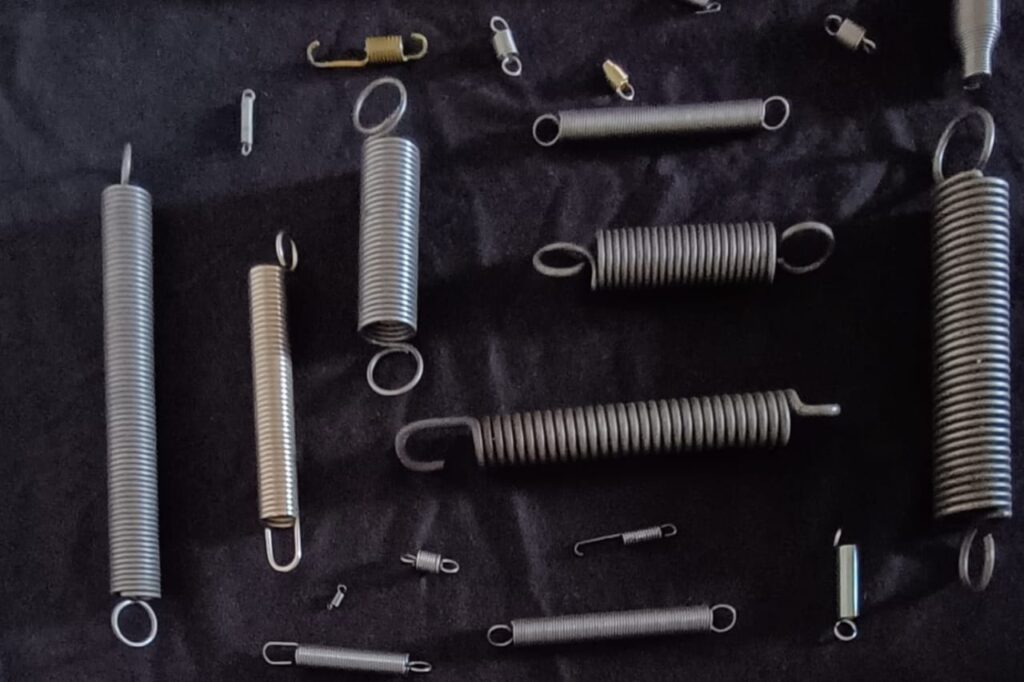

Tension Springs

Home >> Tension Springs

Tension springs are mechanical devices designed to store energy and create a pulling force when stretched. Unlike compression springs that work under a pushing force, tension springs work under a pulling force, meaning they become longer when force is applied and return to their original length when the force is released.

These springs are commonly used in various industries, including automotive, aerospace, consumer products, and industrial machinery, for applications where precise tension is needed to control movement, maintain positioning, or store energy.

Tension Springs Manufacturer in India

If you are looking for tension springs manufacturers in India, there are several leading companies known for producing high-quality tension springs. These manufacturers offer custom-designed springs for various applications in industries such as automotive, aerospace, machinery, and consumer goods.

Features of Tension Springs

- Tension springs are designed to store mechanical energy when extended. The force required to stretch the spring depends on its material, coil thickness, and length.

- Most tension springs come with hooks, loops, or other configurations at both ends to attach them to other components. These hooks allow the spring to be fixed in place while exerting a pulling force.

- Tension springs maintain constant tension as they are stretched, making them ideal for applications where a controlled pulling force is required over a certain range of motion.

- Tension springs can be customized in terms of wire diameter, spring length, coil diameter, and hook configuration to suit specific applications and load requirements.

- These springs are typically made from high-tensile materials like carbon steel, stainless steel, or other alloys to withstand stretching without permanent deformation.

Tension Springs Suppliers in Hyderabad