Oil & Gas Industry

Home >> Oil & Gas Industry

The oil and gas industry is a complex field that involves the exploration, extraction, refining, and transportation of fossil fuels. In this demanding environment, equipment reliability is critical, and springs are essential components that ensure mechanical systems operate safely and efficiently. Springs are used across various applications in the oil and gas sector, from controlling pressure valves to providing critical support in drilling operations. In this article, we will explore the types of springs used in the industry and their specific applications.

Springs are a vital component in the oil and gas industry, contributing to the safe, efficient, and reliable operation of equipment across a wide range of applications. From controlling valves and pumps to ensuring the safety of drilling rigs and pipelines, springs provide essential mechanical support in one of the world’s most demanding industries.

Types of Oil & Gas Industry Springs

Compression Springs

Compression springs are widely used in valves and pumps to resist external forces and control movement. These springs help maintain the correct pressure in drilling and extraction processes.

Torsion Springs

Torsion springs are used in equipment requiring rotational force, such as in drilling rigs and rotary valves. They provide torque and help with energy storage in rotational mechanisms.

Tension Springs

Tension springs store energy by being pulled apart and are essential in equipment such as tension control mechanisms and emergency shutdown systems.

Applications of Springs In Oil & Gas Industry

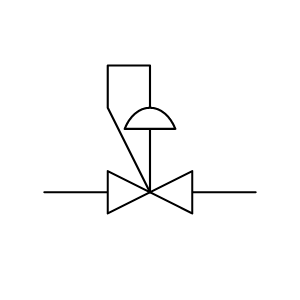

Valve Control and Pressure Regulation

Springs are indispensable in valve systems throughout oil and gas operations, from drilling platforms to refining plants. Compression springs are often used in safety relief valves and control valves, where they ensure that the valve opens or closes based on pressure fluctuations within the system. These valves are critical for preventing over-pressurization in pipelines or storage tanks, which could otherwise lead to dangerous leaks or explosions.In subsea drilling, where systems operate under extreme conditions of pressure and temperature, springs play a vital role in controlling the movement of valves that regulate oil flow and prevent environmental hazards.

Pumps and Compressors

Pumps and compressors are the lifeblood of oil and gas extraction and refining. These systems rely on springs for vibration dampening, pressure balancing, and flow control. Springs help maintain the operational stability of centrifugal pumps, piston pumps, and reciprocating compressors, reducing wear and tear while ensuring efficient flow rates.Compression springs in these systems absorb shocks and prevent mechanical failure by reducing the impact of sudden changes in pressure or flow rates. They also help stabilize rotating parts, ensuring that equipment continues to function effectively under heavy-duty workloads.

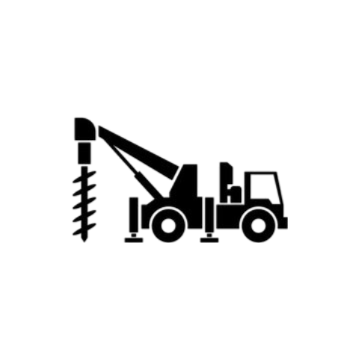

Drilling Equipment and Rig Systems

Drilling operations in the oil and gas industry involve highly sophisticated equipment, including drill bits, derricks, and rotary tables. Torsion springs are used in rotary drilling mechanisms to store energy and provide torque, enabling continuous drilling motion. This is critical in offshore rigs where mechanical systems must function continuously for long periods under high stress.In top drive systems, which are used to rotate the drill string, torsion springs help regulate movement and absorb the mechanical stresses of drilling deep wells. Springs in this context are often custom-engineered to withstand extreme conditions, including high torque and mechanical vibration.

Sealing Systems and Gaskets

Sealing systems in oil and gas operations, such as mechanical seals and gaskets, often incorporate springs to maintain constant pressure between sealing surfaces. These springs compensate for the wear and thermal expansion of components, ensuring a reliable seal that prevents leaks of oil, gas, or other hazardous materials.In rotary seals used in rotating equipment like pumps and compressors, compression springs maintain the required sealing force, even as components expand and contract under varying temperatures and pressures.

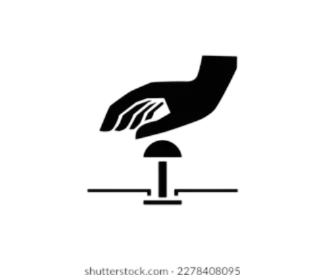

Emergency Shutdown Systems

Safety is paramount in the oil and gas industry, and emergency shutdown (ESD) systems are in place to halt operations instantly if a hazard is detected. Extension springs are integral to many ESD systems, providing the necessary tension to actuate emergency valves or disconnect systems under critical conditions. These springs must be reliable and responsive, ensuring that safety mechanisms are activated without delay in the event of a fire, gas leak, or equipment malfunction.In blowout preventers (BOPs), a critical safety device used during drilling to prevent uncontrolled release of oil or gas.

Subsea and Offshore Applications

The offshore oil industry involves unique challenges due to the harsh marine environment, extreme pressures, and the need for highly reliable systems. Constant force springs and compression springs are used in subsea systems for controlling buoyancy, managing cable tension, and assisting with the deployment and retrieval of equipment.For example, in subsea umbilicals, which provide power and communication to underwater equipment, springs ensure proper tension and prevent tangling or damage to critical cables. In floating production systems, springs support.